In this study, the production of nickel oxide nanoparticles by hydrogen reduction method and from metal chloride in the gas phase has been investigated. These nanoparticles have unique properties that are not found in bulk materials, or micro-scale materials. In this study, the production of nickel oxide nanoparticles by hydrogen reduction method and from metal chloride in the gas phase has been investigated.

The best nickel oxide nanoparticles sales for 2019

Over time, the economy is constantly changing. Especially in the discussion of buying and selling and the market of supply and demand, no one can give a definite opinion about the future of this discussion.

Over time, the economy is constantly changing. Especially in the discussion of buying and selling and the market of supply and demand, no one can give a definite opinion about the future of this discussion.

But given the items we’ve seen in recent years, such as the average price growth of nickel oxide nanoparticles, the supply of nickel oxide nanoparticles on the market, and the amount of customer demand for this product, we can give an expert opinion based on the evidence.

In this section, the properties of Limited nickel oxide nanoparticles are examined. Particle size is a key factor in many applications, especially when the size is below 20 nanometers. Here the particle size is equal to the average numerical diameter (NAD) of the particles, which can be obtained from TEM and SEM images. Differential mobility measurements can be measured.

In addition to the average diameter, the size distribution is often described and used with the standard deviation of the average size. However, for a two-part distribution, the average diameter and standard deviation do not simply provide an exact size distribution.

Especially in catalytic applications, very high surface area and specific surface area are typically measured for nanoparticles. However, if pure nanoparticles with full crystallinity are required, the surface area expressed also indicates the diameter.

The best nickel oxide nanoparticles for export

Imports and exports are always among the most lucrative businesses in the world. Countries that have the technology to produce a product such as nickel oxide nanoparticles sell it to countries that cannot produce The most important nickel oxide nanoparticles. And the cost of transportation and labor is profitable for transportation and taxes and customs. So exporting nickel oxide nanoparticles is always profitable.

Imports and exports are always among the most lucrative businesses in the world. Countries that have the technology to produce a product such as nickel oxide nanoparticles sell it to countries that cannot produce The most important nickel oxide nanoparticles. And the cost of transportation and labor is profitable for transportation and taxes and customs. So exporting nickel oxide nanoparticles is always profitable.

Tactic nickel oxide nanoparticles for sale has been produced for decades using a variety of techniques. One of these methods is to reduce hydrogen. The purity of the powder obtained in this method is very high and today nanoparticle particles are produced with good relative ease.

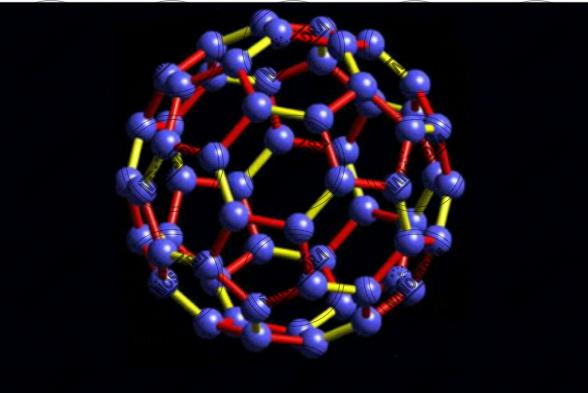

The most active production technologies are plasma processes. There are many different types of plasma methods. A study by Vollath in (2007) has shown that different nanoparticles can be produced using metal precursors and a plasma production method.

Nanoparticles produced by this method have a good distribution. But one of the limitations of these methods is the clumping of manufactured nanoparticles. To prevent clumping in these methods, a low-pressure microwave plasma process can be used. Using this method, it is also possible to produce coverage.

The best cheap nickel oxide nanoparticles?

Regarding the price of nickel oxide nanoparticles, it can be said that it depends on the raw materials used to make nickel oxide nanoparticles and production technology, and the practical method for making nickel oxide nanoparticles.

Regarding the price of nickel oxide nanoparticles, it can be said that it depends on the raw materials used to make nickel oxide nanoparticles and production technology, and the practical method for making nickel oxide nanoparticles.

This produces new products and reduces the use of raw materials. Although the production of metallic nanoparticles has been extensively studied, for metallized metal particles, research on coating mechanisms and economic production methods is still particularly needed.

The method used in this study is a combination of high performance, high production rate, low production costs, high quality of particles, and a good range of the average diameter of existing particles, and other properties. These particles can be used in conductive ink, antenna substrates, medical imaging, or as sensors and catalysts.

Another method of synthesizing these materials is laser evaporation synthesis, which may occur in liquid or in the gas phase. In the latter case, the laser energy evaporates the metal from a suitable target. Nanoparticles germinate from metal in the gas phase. In the gas phase, sintering and agglomeration of particles occur.

Your comment submitted.